Discharge ink removes pigment from the garment similar to 'bleaching' - as opposed to smearing a thick layer of plastic on top on the fabric. This leaves a completely permeable/breathable print, although to get this to work you gotta do a little alchemy. Weigh out the ink, add 10% discharge agent, throw in a little pigment, mix thoroughly and let sit for about 30 minutes

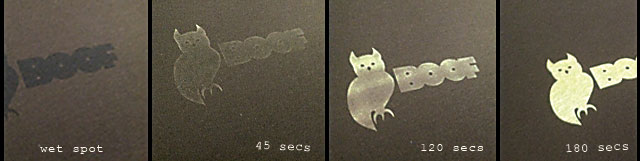

At first the ink just looks like a wet spot. Then as it moves through the dryer it slowly starts to reveal itself.

For the process to work its gotta go through a pizza oven type dryer with forced air for 3 minutes.

Then you get this cool effect - notice how you can see the garment fibers through the ink -

You can pick these up online right now at www.teamscum.com

PS. HOLIDAZE BLOWOUT $ALE - - > > Thurs Dec 8th